We are about to finish our SCADA Training. Before we enter into PLC, You should have some idea n its Basics.

Inputs and Outputs

PLC Basics

A PLC is a microprocessor-based controller with multiple inputs and outputs.

It uses a programmable memory to store instructions and carry out functions to

Control machines and processes.

The PLC performs the logic functions of relays, timers, counters and

Sequencers. It has the following advantages:

Low cost

Reliability

Reprogram ability

Program

Inputs

Outputs

The PLC inputs give it information about the machine or process that it is controlling. These are typically switches and sensors. The switches are connected to an input module that provides the interface between the switches or sensors and the PLC.

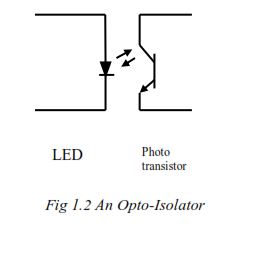

Input module circuits have opto-isolators to protect the internal PLC

circuit from damage.

The PLC outputs are connected directly or indirectly (e.g. through a relay) to actuator controls. Examples include solenoids on directional control valves, motors, motor contactors, alarms and warning lights.

Relay (volt-free): The signal from the PLC operates a relay within the output module connecting the control voltage to the output port and hence to the actuator.

Transistor: A transistor is used to switch on the output. This is faster than a relay output but is only suitable for low power direct current applications.

Triac: This solid state device is used for switching alternating current devices. It requires some form of over current protection.

1. Common port

2. Control Voltage (+)

3. Internal relay contact

4. Output Port

5. Solenoid

Network Protocols

The wiring diagram in shows the inputs and outputs connected directly (hard wired) to the PLC. The devices shown are on/off or digital in nature but the signal to the PLC is analog. Many commonly used devices conform to a 4-20 mA standard whereby signals of 4mA and 20mA form respectively the minimum and maximum values of an analog signal.

With analog devices, a separate cable needs to be run between the end device and the control system because only a single analog signal can be represented on the circuit. The 4-20 mA standards is slowly being replaced by network or field bus communications. Field bus is a multi-drop digital two-way communication link between intelligent devices. Field bus allows the connection of a number of sensors all located in the same area to the same cable. Field buscomes in many varieties depending on the manufacturer and application. Examples include A Sibus, Profibus, Device net and Modbus.

A more recent trend is the development of Industrial Ethernet which has the capacity to transport large quantities of data not only for process control but also to integrate the process with management information systems.

No comments:

Post a Comment